Corrosion Control

ALFA Solution has developed a unique solution for corrosion protection of equipment and materials. If you are in an area that is very humid or have an object that is prone to moisture buildup, you may want to look into using some of our mildew and moisture control products for added protection. Our VCI products work excellent when shipping or transporting shrink wrapped equipment or machinery.

The ProGARDO product line is self standing products based on a special VCI formula using different carriers for application, it can be used for protection of electrical and PLS cabinets, mechanical equipment , spare parts etc. ProGARDO used in combination with our Premium Virgin shrink wrap can protect against corrosion for up to 5 years.

How VCI Works (Simple explanation)

Corrosion is responsible for damage to fabricated metal parts, and also in automobile electronic parts, computer parts, mobile phones and more. During production, storage, or shipping corrosion protection is very important.

Corrosion inhibiting packaging can guarantee that metal components meet required levels of purity before assembly or further processing.

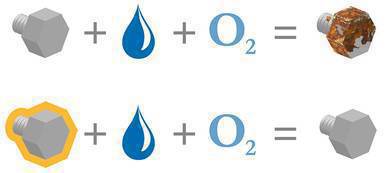

Corrosion is a result of oxidation, moisture or destructive elements coming in contact with the metal surface. Many materials that protect against corrosion such as oil, grease or paint are harmful to the environment and costly to apply. VCI technology works on a molecular level to protect metal surfaces against corrosion and oxidation. VCI works by creating an invisible molecular protection layer on metal surfaces. The corrosion inhibitor migrates out of the packaging products (including film, corrpacks, cargopacks tablets, etc), and into the packaging environment where metal parts are packaged. Tis environment is subsequently saturated with the corrosion inhibitor and a thin molecular protection layer adheres to all metal surfaces. VCI technology works on a molecular level to prevent corrosion and rust on all surfaces of the metal, including recessed areas, holes, and “nooks and crannies”.

VCI stands for Volatile Corrosion Inhibitor and the + sign reflects our special formula that gives the VCI a longer life span. Chemicals used for ProGARDO VCI+ are evaporative materials that when used with different carries like fluid, PE or talcum etc acts inside a closed environment. The VCI molecules evaporate in the enclosed environment and establish a protective coating over the surface of the metals. This protective layer prevents the corrosive elements such as humidity, salts or environmental elements to reacts with the metal surface and will disappear when unwrapped; parts can then be installed directly without any major cleaning process which saves both time and environment.

Metal parts come in many different shapes, weights and sizes. For this reason VCI packaging technology is available in different forms such as film, paper, emitters, tabletts and liquids.

VCI Packaging Film: VCI corrosion protection film can be used in bags, covers, and simply as film. Film VCI packaging can be used to pack large machines, pallets, and bulky parts that need to be wrapped for protection. Film can also be used to package large machines for transport.

VCI Packaging Emitters, Tablets and Liquids: VCI emitters can be used in closed cabinets to protect electrical parts. VCI tablets can be placed in small packages. VCI liquids are also available for coating metal parts. Methods of VCI packaging can be combined to provide the longest and most effective degree of protection metal parts manufacturers need.